Summary of Task Completed

- Complete the Solidworks 3d modeling

- Researched different methods of constructing mounting brackets

- Designed and fabricated 4 types of CNC milled brackets

- Create interactive pdf

Project Development

After reviewing our major milestones the group got together to discuss what tasks had to be competed in order to achieve our goals, as there is only a third of the semester remaining. Our goals have changed quite significantly in what we plan to present as our final output, as we have continually adapted as we continue to learn and find out the best methods of achieving a high result. The main tasks that I have been given were to fix up my Oil Filter model - as I had problems assembling it correctly in Solidworks - and then move on to researching and developing several mounting bracket options that we could use for our hybrid motorcycle.

Complete Solidworks modeling - Oil Filter Fix

The major problem that I encountered with the oil filter is that I was unable to combine and subtract the fins within the inside of the cylindrical object. I realized that this was because I created each component as its own part and then used an "assembly" to put it all together. By experimenting with various methods and tools in Solidworks I eventually found that by placing all of the parts into a single Part file I could achieve the desired goal.

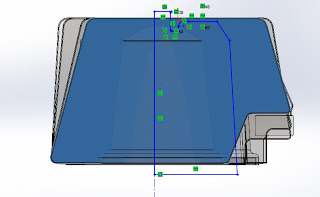

The image below shows the result of modeling the features as separate parts and then placing each part within an Assembly file to construct the Oil FIlter. Although this method seems the most logical, as it allows for greater accuracy with placement of each finn, I could not find a tool that would allow me to subtract the finns mass within the cylindrical part.

To fix this I replicated the cylindrical part and placed it in exactly the same position although within the same sketch as each individual finn. This provided me with a "ghost" of where the finn must be cut (mass removed) in order for it to sit flush with the exterior skin of the cylindrical part (image 2).

|

| image 1 -Shaded blue part is the finn. The blue outline is the overall extents of the finn after removing the mass within the cylinder up to its exterior skin. |

|

| image 2 - The blue outline sketch shows the "ghost" cylinder that must be Cut-removed from the finn. |

|

| image 3 - The shaded dark grey shows the finn after the mass has been removed. |

|

| image 4 - Inaccuracies start to occur using this method. |

Although this method allowed me to create the desired outcome, I still do not believe it is the best way of modeling. This is because often when adjusting the "ghost" sketch to ensure it removes the right amount of finn - so that the finn sits flush with the exterior skin of the cylinder - it is a matter of experimentation and constant adjustments. This can lead to an inaccurate model and also often can be quite deceptive as from one viewing angle the finn may look as though it is sitting flush, from another however there can often be a gap (image 4).

Researching Engine Plate designs

Researching the different methods of manufacturing engine plates was a lot more difficult then we initially anticipated. As we have no experience or knowledge on what engine plates are suitable we split the tasks into 3 categories (CNC milling, cast alumium and tubing).

Engine Plate Designs

|

| Establishing the mounting positions within the frame |

|

| 900 x600mm sheet to be sent to the lasercutter to have our prototype plates made. |

|

| During the first phase of design I printed out a 1:1 CAD drawing of the Honda engine within the Norton frame to establish mounting positions and ensure everything was accurately placed. |

|

| research references |

|

| research references |

|

| Prototype lasercut plates made from 6mm Acrylic. |

Create interactive pdf

The interactive pdf is a tool that as a group we thought would be the best way to present our models to a wider audience of hybrid motorcycle lovers as well as anyone who may be interested in our work. I took on the responsibility of getting this made and although I had never made an interactive pdf before, I found it quite simple to make. Following brief tutorials online I first created all of the necessary pages in a single indesign fileand then used Acrobat Pro to embed the interactivity.

The main features I wanted to include within the pdf were;

- The 3d solidworks models; The aim was to embed the 3d Solidworks models that each group member had created throughout the semester of the honda and norton motorbike, so that viewers can rotate, zoom and view the models however they please. This feature also allows for various types of rendering views and the ability to measure the models whilst in the pdf. This can therefore become very useful for viewers who, whilst constructing there own hybrid motorcycles, can check measurements as a tool for reference.

- 2d CAD drawings; Although we could not place the actual CAD files within the pdf, we did create a sheet for each model part that contained measured drawings in response to the 3d model.

- Renders: Each model parts page also contained a simple render of the part with its designated material. This was not 100% necessary although we thought that it tied everything together quite nicely.

- URL Links; Additionally, the pdf also provided a quick insight into getting prototypes made for things such as the engine plates and provided links to professionals that could have these prototypes constructed.

- Wiki link; The pdf also has a link back to you wiki site and more specifically the e-resources page were viewers can download all of our models in a number of different file types for there own benefit.

Limitations with interactive pdf;

- One major limitation with our interactive pdf was the inability to embed our grasshopper file. This was something that we knew would be impossible as the file type is too different, however if this was something that could be done, I believe it would have had a much greater impact on the overall successfulness of the pdf.

Great information on your site here. I love this post because we can get some useful information from your blog. I expect more post from you guys.

ReplyDeletelongest lasting dermal filler

permanent fillers for face

permanent face fillers

bellafill filler

permanent nose filler

permanent wrinkle filler

long lasting facial fillers

permanent injectable fillers

permanent fillers for acne scars

injectable dermal fillers buy

longest lasting facial filler

artefill injections

bellafill injections

permanent facial filler

line filler injections

bella fillers