Swing Arm

I have finished modeling the swing arm, I think it came out quite well! One major decision I had to make when modeling this part of the bike was my method of modeling in Solidworks. There are two different ways of completing a model within Solidworks; Creating a "part" or an "assembly". Although the swing arm is essentially one "part" of the Honda motorbike, I felt it was necessary to model it as a Honda manufacturing factory would, as an "Assembly" of various parts. This method involves creating each feature as a separate part and then appropriately mating them all together within another file. This method therefore emphasises that different techniques of manufacturing necessary in creating the Swing Part (i.e. Casting, tubing, welding, etc.)

Oil Filter

The major problem that I encountered with the oil filter is that I was unable to combine and subtract the grills within the inside of the cylindrical object. I realized that this was because I created each component as its own part and then used an "assembly" to put it all together. I therefore should have created the whole object within the one "part" for this feature, which would have allowed me to create the desired shape.

Indicators

For the indicators I decided to create the whole feature as a single "part". This is because although there are clearly two distinct features/materials within the component, the pieces fit together without any mating process necessary. If I were to continue modeling, placing in a light bulb I would consider using an assembly and therefore mating the lightbulb face onto the inner bracket.

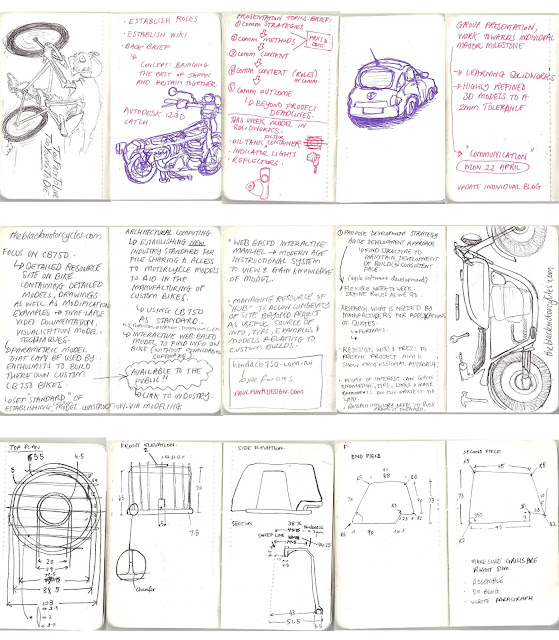

Here are some scans of my note book to date:

.jpg)